Now people’s living standard is getting better and better, and there are more and more people who keep pets, especially dogs. Dogs have become one of people’s favorite pets. With the development of science and technology, the way people keep dogs has changed a lot. Just like the human demand for staple food in addition to three meals a day, will also want to eat some snacks from time to time. With the increasing popularity of keeping pets, many people are also keen to buy snacks for their pets.

Pet snacks

However, the body structure of dogs determines that their food needs are different from those of humans. At present, there are a lot of dog food developed and produced according to the body structure of dogs and the need for nutrition. Among them, snacks such as dog biscuits are favored by many dog breeders as refreshments when dogs play. At the same time, the friction between biscuits and teeth can remove tartar in pets’ mouths, thus achieving the purpose of cleaning teeth and eliminating halitosis.

All kinds of dog biscuits

Pet snack market variety, but also need food machinery to assist high-quality output, with convenience as the main feature of the cat food and dog food puffing equipment is indispensable. The pet biscuit production line is the preferred choice for the production of dog biscuits. This series of production lines can be arbitrarily combined according to users’ requirements of site area and biscuit technology. By changing the mold and process formula, a balanced, rich and delicious dog biscuit can be produced. And the heating mode is diversified, including electric power, gas, heat conduction oil, etc, for customers to choose at will.

Dog biscuit making machine cookie cutter

At present, the fully automatic biscuit production line on the market can realize the full automatic operation from feeding, molding, baking to oil spraying and cooling. Moreover, the biscuit forming machine is equipped with frequency conversion joint control, which is convenient for operation and replacement of biscuit shape. In the baking stage, low-temperature baking technology can simultaneously achieve sterilization and curing effect, to avoid the phenomenon of burnt biscuit products due to repeated high-temperature operations.

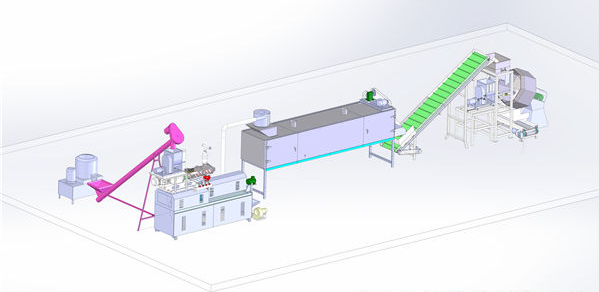

Fully automatic pet biscuit production line

The puffing production line for pet feed includes powder mixer, screw elevator, twin screw puffing machine, oven and other equipment. The material can only be formed by high temperature and high pressure. In this process, harmful bacteria such as e. coli and salmonella can be killed in the raw materials. At the same time promote protein denaturation and starch gelatinization, more conducive to the digestion and absorption of pets.

Features of equipment

1.Biscuit molding machine: the equipment is composed of three parts: leather making, molding and recycling surplus materials;

2.One – time extrusion molding, high molding rate, good molding quality.

3.When changing the product specification, just replace the mold.

4.Drying box way section assembly, easy to install, transport.

5.Drying box: stainless steel mesh conveyor with the furnace, good baking effect.

6.The fuel injector uses frequency converter to control the speed, the speed is stable, the energy saving effect is good.

7.Injector: injector head angle can be adjusted.

8.The parts contacting with food are made of stainless steel, meeting the hygiene requirements of food.

9.High efficiency and energy saving: high thermal efficiency and good power saving effect, reaching more than 30%.

10.The temperature of the oven is automatically controlled, and the control process does not need to be powered on and off repeatedly to achieve uniform heat radiation density, so as to adapt to the desired temperature of different biscuits. It has high reliability, high adjustment accuracy, long service life, easy control and no noise.

At the same time, pet food production line is also widely used in the production of monkey food, bird food, cat food and expanded corn, is the ideal choice for different manufacturers.