- After sale

- Processing PDF

Fast food is suitable for the needs of the rhythm of modern life, and is deeply loved by people. Instant noodles have become the mainstream product, with huge consumption potential.

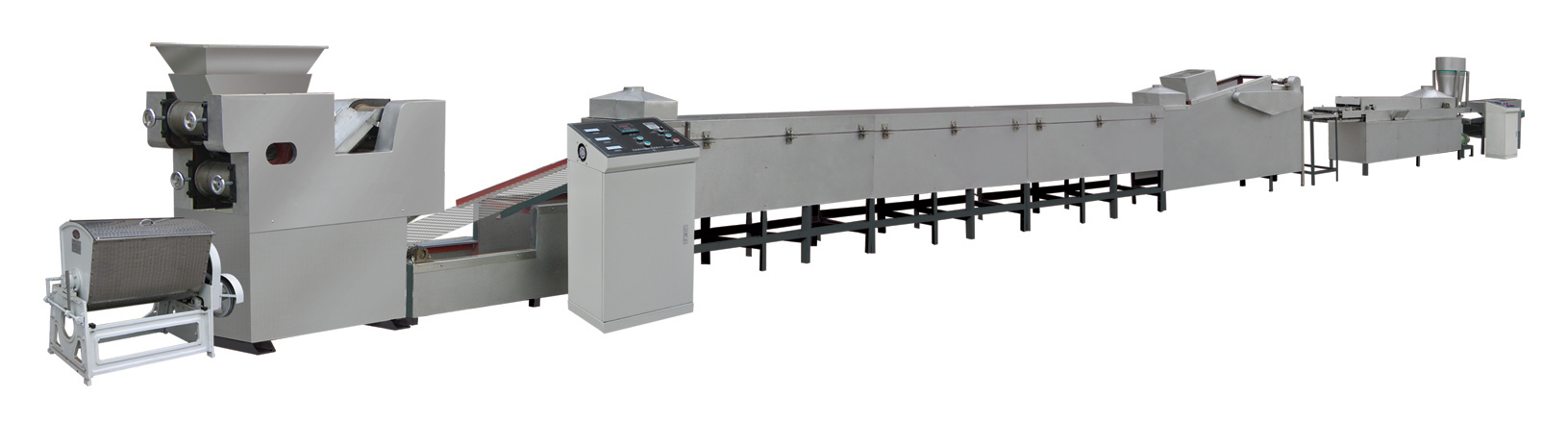

Instant noodle production line is composed of brine mixer, brine metering device, double axis and double speed noodle machine, disc curing machine, compound calender, multi-layer noodle steamer, square noodle cutting and arranging machine, fryer, air cooler, conveyor, etc. it belongs to extrusion food machinery.

Based on the research of similar products at home and abroad, our company produces a new generation of instant noodle production line with miniaturization characteristics, with perfect technology, compact structure, novel design, stable and reliable performance. Production from flour to finished products is automatically completed, with simple operation, moderate output, energy saving, small footprint, with the characteristics of less investment and quick results, especially suitable for small and medium-sized and individual enterprises. The instant noodles produced by the company have the advantages of short rehydration time, good elasticity, smoothness and transparency, and can be compared with the large-scale equipment popular in the market.

Small instant noodle production line

Technical Parameters:

Technical Parameters:

| Model | Installed power | Power consumption | Production capacity | Heating method | Dimensions |

| LTN-E Instant noddle production line | 80.5kw | 50kw | 11000bags/8h | Electrical heating | 23000x1500x1800mm |

| LTN-S Instant noddle production line | 10kw | 10kw | 11000bags/8h | Cooking, frying gas, other electricity | 23000x1600x1800mm |

Technological Process:

Technological Process:

Noodle mixing → shaping → cooking → cutting off → frying pan → cooling

The whole production line is a complete set of advanced environmental protection equipment for instant noodle production with unique production process, novel design, safety and reliability, good appearance and high degree of automation.

Additional configuration of the equipment can be freely selected from flour screen filter, flour conveyor, dough maturing machine, frying oil filter, cooling available air filter, soup feeding machine, packaging machine, metal weight recognition machine, packing machine, etc

Why choose our company?

Our company is an enterprise mainly engaged in the R & D and manufacturing of extrusion machinery, “focusing on the expansion business and serving customers wholeheartedly” is the company’s business service concept, and the company promises to provide customers with timely and in place services. Our company provides a full range of services from production technology to product packaging, to reduce some worries for customers in production. With the innovative ability of professional and technical personnel, our company can also provide customized machine services suitable for customers.

Excellent product quality and perfect after-sales service make our company win good reputation in the industry, all of which ensure every customer’s satisfaction with the order, and also promote our long-term stable cooperation with Malaysia, Japan, Sri Lanka, Pakistan and other regions. The company’s sales network is all over the world, and professional after-sales personnel are ready to go to all parts of the world at any time to provide customers with necessary production process support.

Installation of equipment in Sri Lanka

The company’s goal is to focus on the development of food machinery, focus on improving the interests of customers, constantly provide customers around the world with newer and better products, and create greater value with customers. Customer satisfaction is our greatest pursuit!

We can provide the following after-sales services:

1. Provide production formula, installation and debugging, operation training and other services: professional engineers carry out machine installation and debugging, train enterprise employees to operate skillfully, solve problems encountered in machine operation, and carry out machine maintenance all year round;

2. Professional machine repair and maintenance services: long-term parts warranty and maintenance services, lifetime preferential parts, free equipment warranty for one year;

3. Perfect customer product quality tracking system: establish perfect after-sales quality tracking report, professional analysis and timely feedback for customer products;

4. Non standardized design and production: design and supply non standardized products according to customer requirements to meet customer’s special needs;

5. Based on global customer demand: with the purpose of “serving global customers”, provide all-round consulting and after-sales services in equipment, technology, raw materials, packaging and other aspects, so as to truly make customers worry free.

If you need instant noodle production line, please contact us for more details!

Instant noodle production line Technologies and Processing PDF Download

Instant noodle production line Technologies and Processing PDF Download

Technical Parameters:

Technical Parameters: